We’ve Seen It All. We’ve Done It All.™

DWV System Sub Plan Development and Monitoring for FOG in Commercial Kitchens

In our previous article “Importance of Maintaining Drain, Waste, and Vent Systems in Buildings” (Facilities Executive; September 14, 2020) we explained the importance of creating and using a maintenance plan for any building or facility. In that same vein, this article will focus on an often overlooked and neglected area of maintenance: the grease capture system. As the saying goes, ‘the whole is greater than the sum of its parts,’ and with a maintenance plan, this is especially true. Every section and sub-section of the DWV maintenance plan combines to make it effective. If any part of these section or sub section plans is lacking or not followed, then the overall maintenance plan may be in danger of failing.

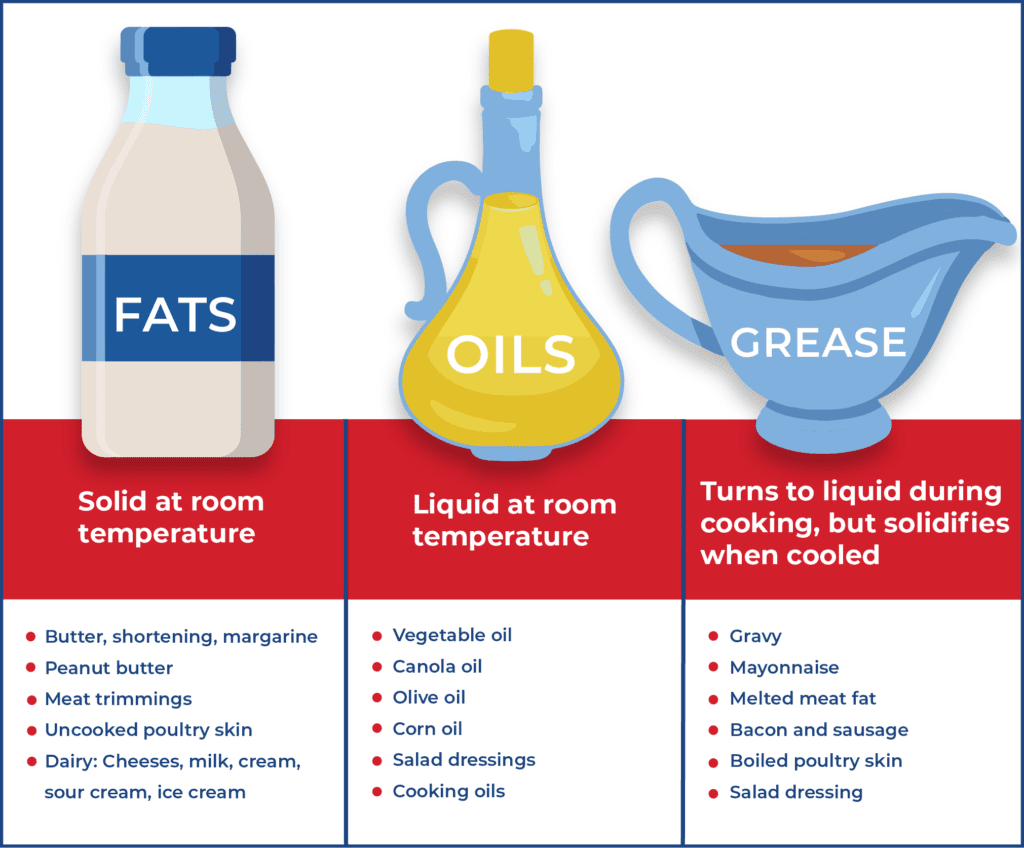

The grease portion of the DWV system includes the piping, drains, grease interceptor, and the conveyance to the disposal point of fats, oils, and grease (collectively known as FOG) waste from the DWV system. If the kitchen plumbing system is not routinely maintained, the functionality and efficiency of the DWV system may become compromised. Additionally, by not removing FOGs at the grease interceptor, they can flow into the municipal sewer system causing catastrophic results.

The Grease Interceptor

The heart of a kitchen grease waste system is the interceptor, but it only functions properly if the supporting DWV system is designed to carry the FOGs to it. Before choosing and installing a grease interceptor, always check with the local authority (AHJ) for any sizing and maintenance requirements that may be required by the local Building or Health Departments. Proper design, sizing, venting, and other considerations should always be incorporated to ensure the best possible solution to the unique conditions of the building structure. This means assessing the conditions, amounts, and types of FOG that will be generated.

Interceptor Sizing

An interceptor sized too large may not appear “full” tempting end-users and maintainers to skip recommended maintenance schedules or increase the time between maintenance to lessen costs. However, an interceptor begins to go septic after 30 days when not emptied. When this happens, microorganisms begin to break down the grease-laden waste thus acting like a septic tank as the waste decomposes. This process lowers the pH in the interceptor and releases odors that are not suitable for a food service facility. Conversely, if the intervals of cleaning are frequent due to the interceptor being sized too small, the cost of maintaining the interceptor increases. When interceptors are not cleaned frequently enough, FOGs can pass through and be discharged into the municipal sewer system.

Sub Plan Development

Once the above items are considered and installation of the kitchen grease waste system is completed, a maintenance plan can be created. This starts with an assessment schedule for inspection of the accumulation of grease-laden waste in the interceptor to determine the frequency of cleaning. The intervals of inspection should be close enough to fully assess the volume of materials being held by the interceptor and to identify the amount of time between cleanings required. According to the article “Grease Interceptor Facts and Myths” (Plumbing Systems & Design; November 2007) by Max Weiss, “A rule of thumb, though not formally prescribed by code and rarely by pretreatment administrators, is 25 percent of the wetted area of the interceptor.” It further provides a method for the assessment:

“The simplest method to estimate the time it takes a given interceptor to reach 25 percent is inspecting frequently, daily in heavy loading circumstances and recording the intervals between cleaning until a pattern of accumulation is apparent. Under no circumstances should that interval be greater than 30 days, except for GRD’s and FOG disposal systems, where manufacturers’ instructions prevail.”

Once the assessment is completed the timeline for cleaning can be established and the maintenance plan can be created. If things change and the chosen interval of cleaning is found to be insufficient, then reassessment should be completed.

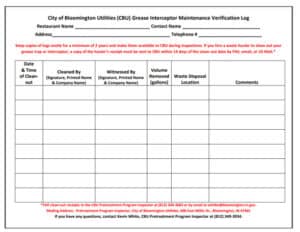

Maintenance Log

Critical to the maintenance plan for the grease interceptor and associated DWV system is to create a log that tracks all maintenance and cleaning of the system. This ensures that the plan is being followed and can also include information that would be pertinent to the assessment such as conditions for grease accumulation. In other words, if a notable change in grease generation occurs by adding equipment, changing a process, or higher than normal usage, then the plan should be reviewed and updated to reflect this information for future reference. This may include seasonal changes in high grease generation. The maintenance plan should be updated to reflect the new volume of grease waste.

Building Owners and Tenants

When a building owner has tenants with kitchens that require the use of grease interceptors, a building maintenance plan should be required. This plan would include a mechanism for assessing maintenance needs based on specific conditions for proper maintenance and cleaning which is the tenant’s responsibility. This plan should also include a verification checklist so that the building owner is able to verify that the tenant is following the prescribed maintenance plan for the building. Verification of proper maintenance becomes a risk mitigation tool for the building owner, since the building owner may be responsible for grease that enters the municipal sewer system or affects other tenants in the building. Both the building owner and tenant are responsible for the system.

When a building owner has tenants with kitchens that require the use of grease interceptors, a building maintenance plan should be required. This plan would include a mechanism for assessing maintenance needs based on specific conditions for proper maintenance and cleaning which is the tenant’s responsibility. This plan should also include a verification checklist so that the building owner is able to verify that the tenant is following the prescribed maintenance plan for the building. Verification of proper maintenance becomes a risk mitigation tool for the building owner, since the building owner may be responsible for grease that enters the municipal sewer system or affects other tenants in the building. Both the building owner and tenant are responsible for the system.

Building owners need to establish and document minimum requirements for correct grease removal. Tenants need to follow the guidelines for proper cleaning and maintenance of the grease interceptor. Lastly, building owners should conduct a physical inspection to confirm grease waste is removed correctly in accordance with the maintenance plan.

DWV System Maintenance Best Practices

The DWV system maintenance plan should include the entire plumbing system, not just the grease interceptor. This includes inspection of the DWV system that conveys the kitchen waste. Adequate maintenance limits the potential downtime caused by failures and stoppages. By establishing a scheduled maintenance plan, it is easier to accomplish inspections and needed repairs or maintenance when convenient rather than during peak hours of operation.

The above is not a complete list but should be used as a building block to establish a maintenance sub plan for a commercial kitchen DWV system. In the case of the grease portion sub-plan, changes and assessments will occur and the plan should be reviewed and updated periodically. A sub plan that assesses, verifies and is tailored to fit the requirements, while easy to follow and verify, will make a quality addition to the building maintenance plan.

Figure 1. Example of a Grease Interceptor Maintenance Log

NOTE: Grease interceptor maintenance is regulated by the Heath Department and monitored by the Water Quality Department.

Want to Learn More?

In case you missed it, read the article referenced above, “Importance of Maintaining Drain, Waste, and Vent Systems in Buildings,” for more information on the best way to maintain a building’s DWV system.

Contact the Institute’s Cast Iron Crew for additional information. Use the button below to find the CISPI crew member in your area.

FIND YOUR CISPI REP TODAYSubscribe to CISPI eNews

Subscribe to the Institute’s eNewsletter, Cast Iron Crew News.

Subscribe NowContact Us

Need assistance or technical information on cast iron soil pipe and fittings?

Find your CISPI RepSubscribe to CISPI eNews

Subscribe to the Institute’s eNewsletter, Cast Iron Crew News.

Subscribe NowContact Us

Need assistance or technical information on cast iron soil pipe and fittings?

Find your CISPI Rep