The Quiet Pipe

With fire resistive construction or underground installations, the differences between plastic and cast iron are hidden from view. But there’s no hiding the differences in sound attenuation in above ground installations.

Simply put – there is no piping system quieter than cast iron. No one wants to hear the gurgling and sloshing sounds of water from fixtures on floors above flowing down the walls, especially in high-rise condominiums, commercial office buildings or high-end hotels.

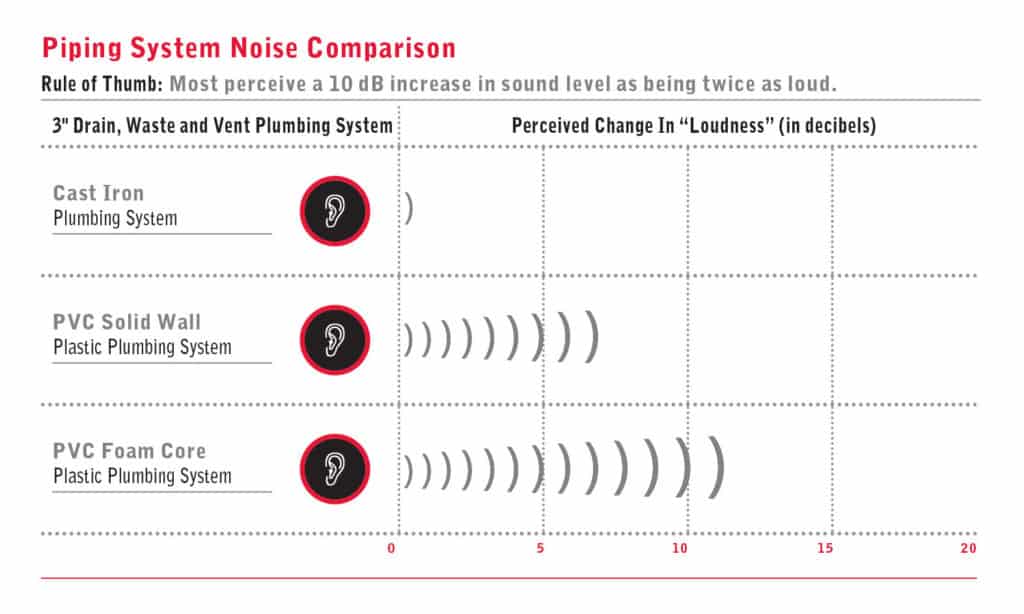

Using cast iron for waste piping will result in a plumbing system that is up to 11 times quieter as compared to an all-plastic system.

Cast iron’s microstructure is the primary factor in its sound-dampening quality. The graphite flakes act to dampen out any vibration applied to the iron, reducing noise. But its microstructure isn’t cast iron’s only advantage when it comes to noise.

The method of joining sections of pipe together also plays a key role. The neoprene rubber gaskets used in cast iron installations keep each section of pipe from touching, thus eliminating any contact-related sound. Plastic systems are solvent cemented into rigid systems that can create noise as they expand and contract with heating and cooling.

Some “fixes” that plumbers attempt to solve plastics noise problems may not actually fix the problem, and they add expense. Wrapping plastic pipe in insulation to muffle the sound of water cascading through the pipe can create a solid barrier between the pipe and the wall that can end up being sound-enhancing rather than sound deadening. And, the time and materials involved in wrapping plastics in insulation adds cost to the installation.