Rely on Cast Iron for Underground Installation

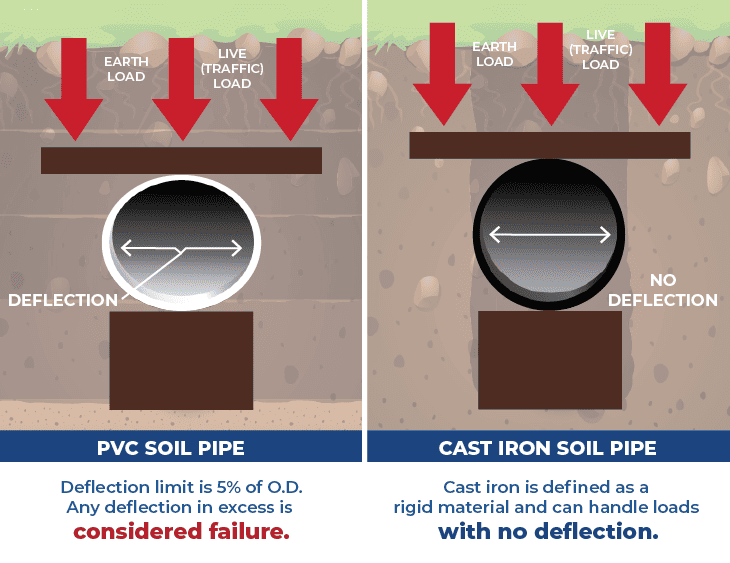

Proper underground installation is one of the most misunderstood piping applications. Underground piping is expected to support not only the earth load, but the live (traffic) load above it as well, all while limiting deflection that can cause joint leaks.

Like Eggs, PVC Pipe Needs Protection

Defined as flexible systems, plastic piping is subject to deflection if not properly installed. The point of failure for plastic pipe is deflection in excess of just 5% of the inner diameter of the pipe, according to the ASTM D 2321 standard.

“This 5% limit means only a quarter inch in deflection

in a four-inch pipe is defined as a failure.”

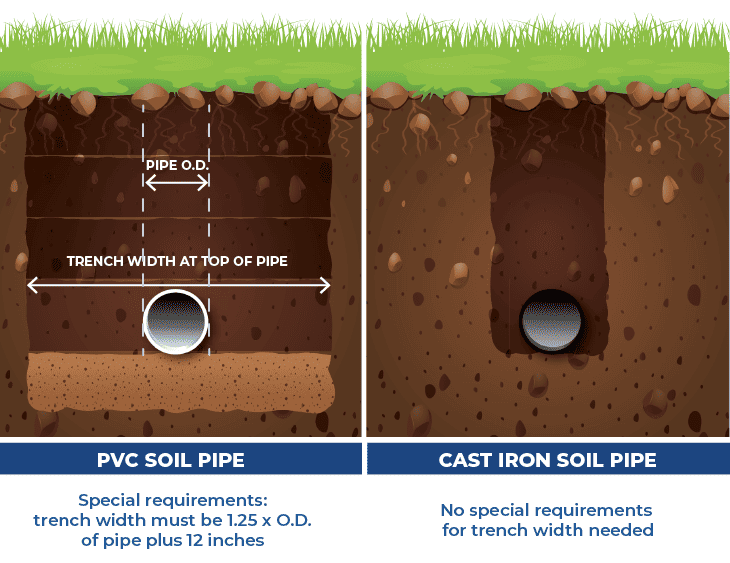

PVC underground installation is dependent on sidefill stiffness to limit deflections. For PVC, the trench is required to be the width of the pipe O.D. plus 16 inches or pipe O.D. times 1.25 plus 12 inches.

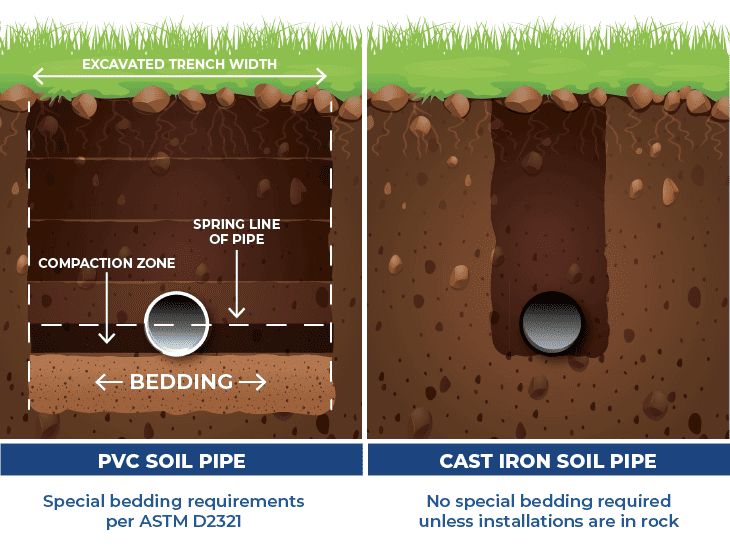

For example, a six-inch pipe would require a 20-inch wide trench – that’s a lot of extra digging on the front end and extra compaction on the backfill. Compaction in six-inch maximum layers – done by hand- is required by ASTM D2321. Depending on the soil type, minimum compaction density can range from 85% – 95%.

The trench for plastic pipe also involves special bedding requirements. There must be a minimum of four inches of bedding material, depending on the soil type, to support the pipe. ASTM D-2321 provides a classification chart for determining the type bedding for varying conditions. In rock excavations, a minimum cushion of six inches is required below the bottom of the pipe.

PVC installation requires more excavation, sidefill and compaction to support the pipe wall. This increases time and installed cost of the product dramatically.

There’s Strength in Iron

Cast iron pipe is up to 10 times stronger than thermoplastic. It’s defined as a rigid material and can handle the earth load and live (traffic) load with no deflection. It does not need the compaction of the sidefill to support the pipe wall, so the trench can be as narrow as the installer wants.

The physical properties of cast iron soil pipe make it the best DWV (Drain, Waste, and Vent) material for underground installation. The two keys to proper underground installation are trench preparation and backfilling. Learn more about cast iron underground installation best practices: https://www.cispi.org/undergroundinstall/

Training & Education

The Institute provides in-person training, including lunch and learns, technical forums and more.

Contact your local territory manager below to schedule a training.

Learn MoreFor More Information

The CISPI Cast Iron Soil Pipe & Fitting Handbook offers detailed information on the manufacture and use of cast iron.

Download the HandbookTraining & Education

The Institute provides in-person training, including lunch and learns, technical forums and more.

Contact your local territory manager below to schedule a training.

Learn MoreFor More Information

The CISPI Cast Iron Soil Pipe & Fitting Handbook offers detailed information on the manufacture and use of cast iron.

Download the Handbook