Underground DWV Plumbing Systems

Save Time and Money when Installing Cast Iron DWV Plumbing Systems Underground

Proper underground installation for DWV plumbing systems is key to performance and success. Understanding the specifications, requirements and best practices can make a difference in a plumbing system’s durability and longevity. This article highlights what may happen when plumbing products are not installed properly, and how to ensure performance through the correct installation in underground applications.

Value Engineering Costs More in the Long Run

Proper installation of underground DWV plumbing systems is important. But sometimes, especially when the specification is changed, problems occur that can have far-reaching consequences. One example is the Louis Armstrong International Airport, located in the New Orleans metropolitan area.

The Louis Armstrong International Airport was a construction project riddled with delays including problems with the new PVC DWV plumbing system installed underground. 127 cracks occurred in 350 of 15,000 linear feet of the drainage line[1]. Even though engineers planned to limit gradual sinking of the subsurface by using 5,000 piles[2], local code officials warned that subsidence would occur with the soil beneath the terminals. Due to these soil conditions, the recommendation was made to place hanger support every two feet. Contractors claimed it would be cost-prohibitive to install hangers every 2 feet. The estimated cost for materials was calculated at $22,000 ($6 per hanger), plus the additional costs for labor to install them[3].

A compromise was agreed to between the contractor and the city of Kenner, Louisiana. Hanger supports were installed every three feet instead of the 2-foot recommendation[4]. When city inspectors checked the project, they found breaks in sections of the pipe every three feet. Repair costs associated with cutting and digging through the foundation to repair the damage, on top of the additional $22,000 spent to hang the piping that ultimately failed, far exceed the initial savings on material value engineering.

Underground Installation Best Practices

Regardless of the materials used for a plumbing system, underground installation must follow standards to ensure product performance. Cast iron pipes are a rigid piping material and have increased stiffness. Cast iron does not have the same rate of deflection as flexible piping materials like PVC. Underground PVC installation standards call for specific excavation, bedding, backfill, and compaction to provide additional sidewall support of the pipe.

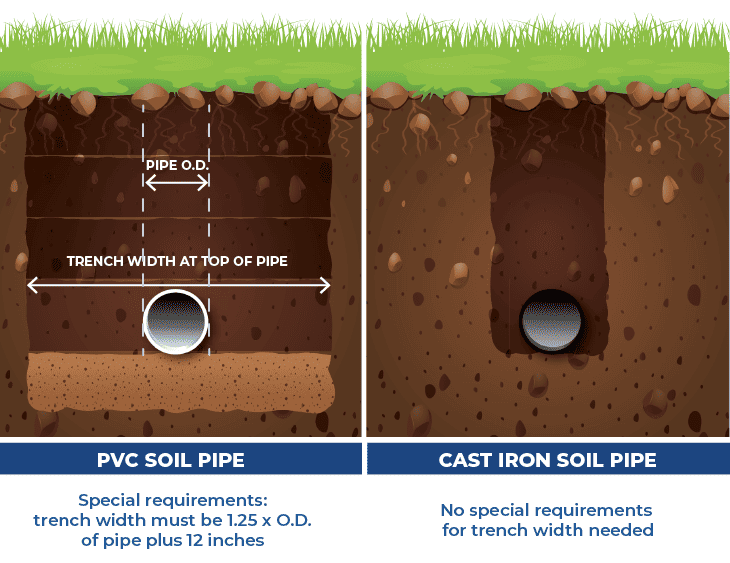

ASTM D2321 (Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications) defines the requirements for bedding and backfill. Digging a larger trench is the first step to installing PVC underground. A larger trench provides more surface area for backfilling and compaction. For example, the minimum width of the trench should be the outside diameter of the pipe plus 16 inches. For a 4-inch pipe, the trench would need to be 20 inches (4 + 16). The trench width provides enough room for joining the pipe and the space required to backfill and compact the backfill materials. Additionally, the space between the pipe and trench wall must be wider than the equipment used to compact that backfill.

Also found in ASTM D2321 are requirements for trench depth, backfill material, dewatering, and compaction best practices. If insufficient backfill and compaction is used, the system is in jeopardy of failure. An under-slab failure as described in the Louis Armstrong International Airport example, highlights the consequences faced when a failure in a hard-to-reach location is not considered.

In contrast, cast iron pipe material is rigid and does not require the additional trench width, depth or sidefill compaction to ensure deflection does not occur.

Pipe may be buried beneath a building built on unstable soil by suspending the piping systems from structural slabs. Hanger support should be installed in accordance with ATSM F2536 (Standard Guide for Installation Plastic DWV Piping Suspended from On-Grade Slabs).

When planning and specifying a DWV plumbing system, include all tasks and materials included for installation, including excavation, backfill, compaction, additional soil types if needed and the labor needed to install in accordance with ASTM D2321when utilizing plastic DWV piping. When comparing plastic DWV materials to cast iron DWV piping, by proper installation requirements, cast iron pipe is the “simple” choice.

Refer to the CISPI 301 Standard, Chapter 6 Suggested Installation Instructions for more information on cast iron pipe underground installation, or ASTM D2321 for PVC plumbing systems.

Contact the Institute’s Cast Iron Crew for more information on plumbing installation and best practices.

[1] https://www.nola.com/news/another-problem-crops-up-at-new-airport-terminal-in-new-orleans-opening-date-still-a/article_2ada82d2-b3cf-11e9-a97d-17bb838bb5ec.html

[2] https://www.aviationpros.com/airports/buildings-maintenance/terminal-maintenance/news/21094793/airport-officials-issues-with-new-terminals-drainage-system-nearly-fixed-still-set-for-fall-opening

[3] https://www.wwltv.com/article/news/airport-terminal-contractors-ignored-inspectors-warnings-leading-to-plumbing-problem-that-pushed-opening-date-back/289-e1502968-c7a3-484c-93f2-cf91daf10151

[4] https://www.enr.com/articles/47373-plumbing-problems-ground-new-orleans-airport-terminal

Training & Education

The Institute provides in-person training, including lunch and learns, technical forums and more.

Contact your local territory manager below to schedule a training.

Learn MoreFor More Information

The CISPI Cast Iron Soil Pipe & Fitting Handbook offers detailed information on the manufacture and use of cast iron.

Download the HandbookTraining & Education

The Institute provides in-person training, including lunch and learns, technical forums and more.

Contact your local territory manager below to schedule a training.

Learn MoreFor More Information

The CISPI Cast Iron Soil Pipe & Fitting Handbook offers detailed information on the manufacture and use of cast iron.

Download the Handbook